In the age of technology, customization and personalization are becoming more and more important. Consumers want products that fit their individual needs and tastes.

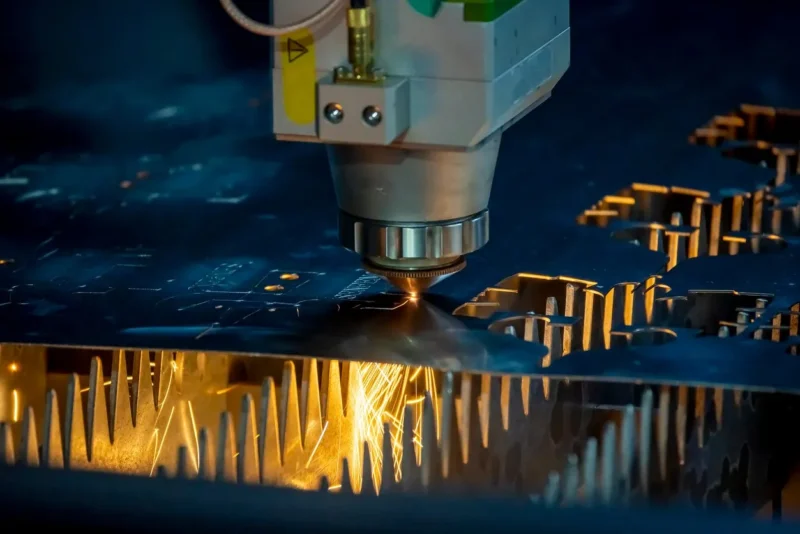

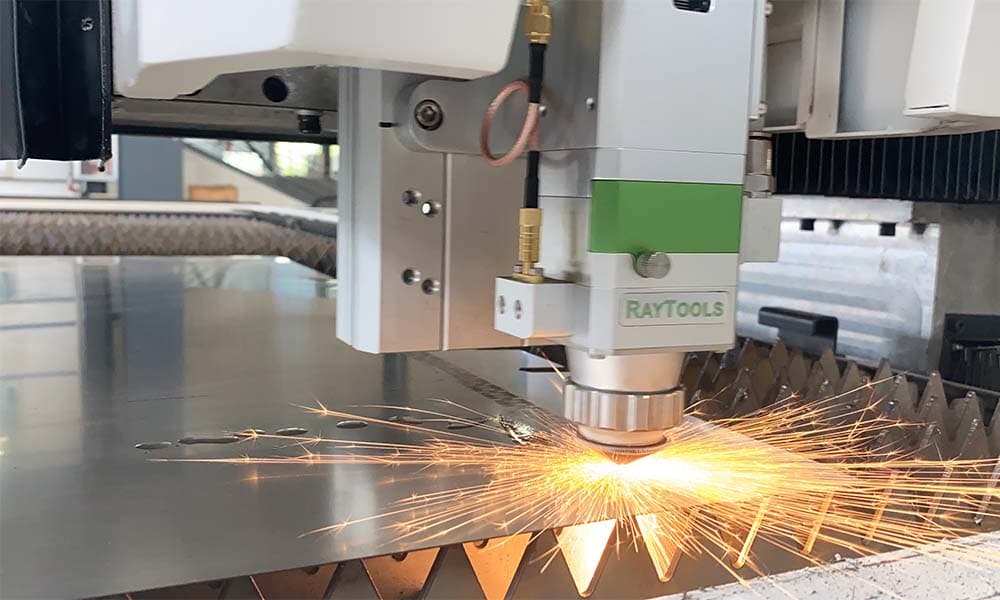

Nowadays, laser machines are revolutionizing the way consumer products are made by allowing for greater levels of customization than ever before. From designing intricate patterns to engraving personalized messages on a variety of materials like wood, glass, or stone – laser machines enable people to take control over how their items look or function.

In this article, we will explore how these amazing tools can help you create unique items tailored to your exact specifications.

Laser Machines: Transforming the Way We Customize and Personalize Products

Laser machines have revolutionized the way we customize and personalize products, allowing consumers to turn everyday items into their unique works of art. From t-shirts to mug1s and even furniture, laser machines are transforming the way we produce personalized goods.

With a wide range of features such as engraving, cutting, marking, and more, these powerful machines can quickly create intricate designs with precise accuracy. Laser machines enable businesses to offer customers high-quality customized products that are tailored specifically for them – something that was not possible before this technology existed.

Thanks to laser technology, companies now have an easier time creating custom pieces in bulk quantities at competitive prices while still providing customers with a quality product they are sure to love. Whether it’s for promotional materials or special gifts for someone special – laser machines make customization quick and easy!

Unlocking Creative Potential with Laser Machine Technology

Laser machine technology is revolutionizing the way consumers design and personalize products. With laser machines, manufacturers can produce customized items with unprecedented precision and detail.

By unlocking creative potential with this advanced technology, companies can offer an unparalleled consumer experience that meets individual needs while also allowing for a wide range of customization options. Consumers no longer have to settle for mass-produced items; instead, they are now able to create truly unique pieces that reflect their style and personality.

Laser machines also make it easier than ever before for designers to bring their ideas to life without investing in expensive tools or equipment. This technology has opened up new possibilities not only for businesses but also for individuals who want a more personalized product that stands out from the crowd.

The Benefits of Utilizing Modern Laser Machinery for Design Purposes

Modern laser machinery provides businesses with the opportunity to produce customized and personalized products for their customers. From jewelry engravings to personalized signage, modern laser machines allow designers to create unique pieces tailored precisely to the customer’s needs.

With these machines, complex shapes and intricate details can be crafted at a fraction of the cost that would come from manual labor or traditional manufacturing methods. The technology behind laser cutting is also incredibly efficient when it comes to accuracy and precision.

Laser-cut objects have extremely precise edges which are perfect for detailed designs such as logos or patterns that require exact measurements to deliver a professional finish. Moreover, since no contact is required between the machine and the material being cut, there’s less chance of damaging either one during production – meaning businesses can produce high-quality items quickly without worrying about costly errors or mistakes.

In addition, utilizing modern laser machinery allows designers to get creative by personalizing consumer products in ways never before possible with traditional methods – adding an extra layer of customizability that customers will appreciate when making their purchase decision. By using software solutions integrated into these machines they can easily adjust settings like speed and power output giving them more control over how exactly each item turns out; something simply not achievable through other means due to time constraints or cost factors involved in achieving a desired result manually.

Finally, thanks to its affordability compared with other forms of industrial design processes such as die casting or 3D printing, incorporating modern laser machinery enables organizations across all industries to gain access to tools previously unavailable due to budget restrictions while still delivering high-quality results every time!

Conclusion

Laser machines have revolutionized the process of customization and personalization, making it easier than ever for consumers to create unique products that meet their exact requirements. By eliminating manual processes and streamlining digital production, laser machines have drastically improved the speed and quality of custom-built products while providing a more cost-effective solution. With this technology leading the way in consumer product innovation, there is no limit to what creative minds can come up with when using laser machines.

From personalized gifts to one-of-a-kind home décor items, these cutting-edge tools are redefining how people express themselves through products.